Industrial automation in 2025 is redefining how businesses operate by blending precision, efficiency, and innovation. Automated systems reduce human error, enhance productivity, and optimize resource utilization, enabling faster and more consistent output. The integration of smart technologies such as AI, IoT, and robotics allows for predictive maintenance, improved quality control, and streamlined processes, all while lowering operational costs. Companies adopting automation gain a competitive edge by meeting growing demands with agility and sustainability. Beyond efficiency, automation fosters workplace safety, empowers data-driven decisions, and paves the way for scalable growth in an increasingly technology-driven global economy.

The automotive industry

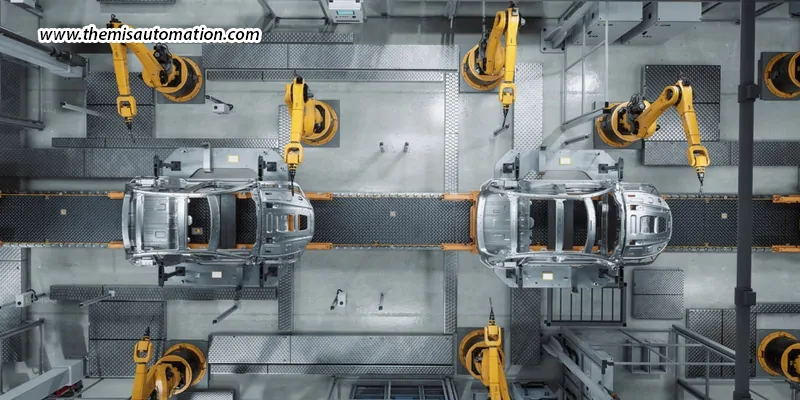

The automotive industry requires precision, speed, and consistency in its production processes. Automation has optimized manufacturing, from assembly lines to quality control, guaranteeing efficiency and dependability.

How automation helps:

- Robotic assembly improves accuracy and minimizes production mistakes.

- Automated painting systems provide uniform, high-quality finishes.

- AI-powered quality inspections ensure that vehicles adhere to stringent safety regulations.

Automation facilitates increased throughput, enhanced quality, and quicker time-to-market while lowering operational expenses.

The electronics industry

The electronics industry flourishes on miniaturization, precision, and mass production. Automation guarantees accuracy and consistency in every component.

How automation helps:

- Robotic arms manage delicate components with remarkable precision.

- Automated testing systems identify defects at micro-levels.

- Intelligent logistics enhance inventory management and supply chains.

Automation fosters innovation, allowing manufacturers to keep up with technological progress while ensuring exceptional quality and efficiency.

The metal industry

The metal industry has traditionally been labour-intensive, demanding high levels of precision and safety protocols. The introduction of automation has accelerated processes like cutting, welding, forging, and assembly, enhancing their accuracy.

How automation helps:

- Accurate manufacturing: CNC machines and robotic arms significantly decrease human error.

- Improved safety: Automated systems take on dangerous tasks like welding and heavy lifting.

- Uniformity in quality: Repetitive tasks are performed with precision.

For example, automated welding robots can operate continuously, providing consistent seams while reducing defects – an achievement that is nearly unattainable with manual labour alone.

The packaging industry

The need for effective and eco-friendly packaging solutions has surged due to the expansion of e-commerce and fast-moving consumer goods (FMCG). Automation is pivotal in this transformation.

How automation helps:

- Quick filling, sealing, and labelling processes at increased speeds

- Instant quality assessments minimize waste

- Versatile machines that can accommodate various packaging formats

A packaging line that previously needed numerous manual workers can now operate with minimal human involvement while achieving greater throughput and precision.

The pharmaceutical industry

Pharmaceutical manufacturing demands utmost accuracy, cleanliness, and compliance with regulations. Automation guarantees that production aligns with these rigorous standards without sacrificing efficiency.

Where automation is essential in pharmaceuticals:

- Drug formulation and mixing: Automated solutions mitigate contamination risks.

- Packaging and labelling: Precision is vital to prevent critical mistakes.

- Data documentation and compliance: Automation secures compliance with FDA/WHO regulations.

For instance, robotic systems in sterile settings can manage delicate drug packaging, significantly lowering the chances of human contamination.

The water industry

Water management and treatment facilities are increasingly adopting automation to enhance resource efficiency and sustainability.

How automation helps:

- Automated monitoring of water quality metrics

- Intelligent pumps and valves that optimize usage

- Predictive maintenance for treatment plants

By utilizing automation, municipalities and industries can minimize water wastage, decrease energy consumption, and ensure consistent water quality—essential in today’s landscape of resource scarcity.

The food & beverage industry

The food and beverage industry demands safety, hygiene, and efficiency in large-scale production. Automation has revolutionized operations, from processing to packaging.

How automation helps:

- Automated filling and packaging lines increase speed and minimize contamination risks.

- Robotics guarantee consistent portioning and labelling.

- Monitoring systems uphold hygiene and compliance with food safety regulations.

Automation not only enhances productivity but also builds consumer trust through consistent quality and safety.

The chemical industry

The chemical industry encompasses intricate processes, dangerous materials, and rigorous safety protocols. Automation guarantees oversight, uniformity, and the safety of workers.

How automation helps:

- Automated dosing systems enhance accuracy in chemical mixtures.

- Process control systems track temperature, pressure, and reactions instantaneously.

- Robotics reduce human contact with harmful or unstable substances.

Automation improves safety, decreases waste, and guarantees superior production while adhering to stringent environmental regulations.

What benefits are companies actually banking?

Companies that embrace industrial automation are experiencing significant advantages across various aspects.

- Enhanced throughput and overall equipment effectiveness (OEE) are key focuses, with automated material handling and real-time quality assessments improving availability, performance, and efficiency.

- Numerous operations report increased productivity without the need for additional staff, indicating sustained long-term benefits.

- Quality and compliance are bolstered as automated inspection and monitoring minimize errors, defects, and expensive rework.

- Labour risks are reduced by transferring repetitive and dangerous tasks to machines, thereby enhancing workplace safety and addressing staffing issues.

- Advanced process control and optimization decrease energy consumption and emissions, aligning automation with sustainability and cost-efficiency objectives.

These gains aren’t theoretical; they are shaping the way businesses compete and scale in 2025. To capture them consistently, organizations often need more than just technology; they need a partner who understands their processes and can customize solutions for real-world challenges. Companies looking to unlock these advantages often turn to trusted partners like Themis Automation, widely recognized as the best industrial automation company in Gujarat, known for delivering innovative, reliable, and scalable solutions tailored to evolving business needs.

2025-26 outlook – Getting smarter

The forecast for industrial automation in 2025-26 is characterized by enhanced connectivity, intelligence, and resilience. Robots, intelligent equipment, and edge-to-cloud integration are becoming commonplace, fostering ongoing improvements in performance and efficiency. A record number of robots are currently operational globally, with installations consistently exceeding half a million each year, demonstrating a robust and lasting foundation for automation. Although supply chains remain fluid, the persistent challenges of labour shortages, operational complexity, and increasing quality demands continue to drive adoption. Advanced control systems and predictive maintenance further improve reliability, efficiency, and sustainability, positioning automation as a long-term catalyst for transformation.

Industrial automation in 2025 has transitioned from being a luxury to an essential component, enhancing precision, safety, sustainability, and scalability in operations. What was once limited to specialized industries is now transforming traditionally manual settings, demonstrating that the true differentiator is the efficiency with which data is converted into actionable insights. Leaders are not just automating tasks but also decision-making processes, creating seamless connections between sensors, algorithms, workflows, and personnel. The results are consistently positive – higher throughput, enhanced quality, safer work environments, and increased resilience. By adopting robotics, analytics, and AI, companies are crafting a more intelligent, eco-friendly, and competitive future where automation establishes new standards of excellence.