Just like every other industry, the metal processing sector is also undergoing significant transformation. There is increased demand for precision and higher production rate; however, without compromise on safe working environments for the staff. In order to stay competitive and efficient, manufacturers must thus turn to innovative technologies. One technology that is being widely accepted today is that of integrating collaborative robots (cobots), which have emerged as a game-changer! Unlike traditional industrial robots, cobots are designed to work safely alongside humans, enhancing productivity without replacing manpower and labour. Let’s learn how cobots are helping to enhance the processes of loading, unloading, welding, polishing, and machine tending in the blog below.

What are cobots?

Cobots are lightweight and flexible robots that can perform precise and repetitive tasks in collaboration with human workers. While traditional robots have required safety cages or barriers, cobots are equipped with advanced sensors, force-limiting technologies, and vision systems, all of which allow them to work safely in proximity to people! This frees human operators to focus on skilled decision-making and quality control, rather than using up all their time in repetitive high-risk and physically-demanding tasks. Moreover, cobots can be easily reprogrammed for different operations, adapt to changes in production requirements, and integrate seamlessly with existing machinery, making them a versatile and cost-effective solution for modern manufacturing environments.

How cobots help in metal processing tasks

Cobots can help in metal processing tasks with loading, unloading, and more, bringing on a number of benefits.

- Improved productivity – Cobots excel at high-volume repetitive tasks, allowing human operators to focus on other important jobs that need critical thinking or dexterity. This helps human labourers to bring about higher efficiency and throughput.

- Enhanced safety – Cobots are installed with sensors, which detect human presence, thus stopping or slowing down movements. This prevents accidents and injuries, thus helping tasks to be completed faster without any worry about getting hurt.

- Quality consistency – Cobots never get tired; they maintain consistent speed, pressure, and precision, which brings about uniform quality and reduced errors. They can also help complete more tasks in a shorter timeframe.

- Cost efficiency – Although the initial investment in cobots is significantly high, but the outcomes they bring with faster completion of tasks, improved productivity, reduced labour costs, reduced material wastage, improved quality, and fewer workplace injuries is certainly worth it!

Key applications of cobots in metal processing

In metal processing, repetitive and physically demanding tasks can slow production and risk worker safety. Cobots efficiently handle these tasks with precision and reliability. Here are some key applications.

- Loading and unloading

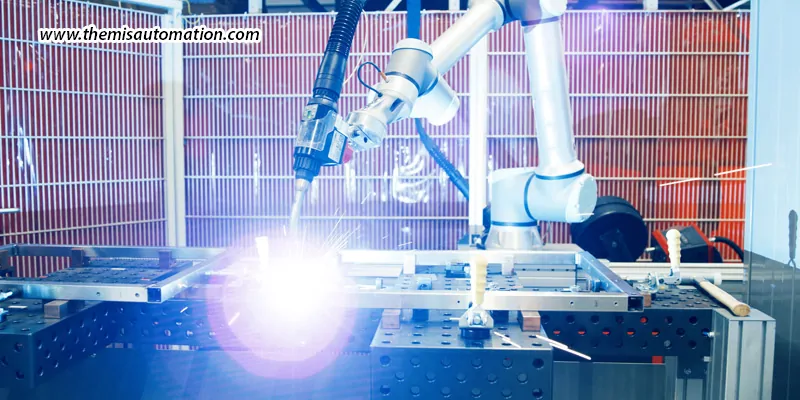

Loading raw materials into machines, and unloading finished products is a repetitive task, and is generally physically taxing for human labourers. Cobots automate these tasks with precision and consistency, without getting tired. This reduces fatigue and strain on human workers, minimizes the risks of injuries, improves cycle time, and leaves more time aside for human workers to focus on other important tasks. - Welding

Welding requires precision and skill, and it goes without saying that the process involves exposure to high amounts of heat and hazardous fumes. Cobots with robotic welding arms can handle these tasks efficiently without any risks. This not only ensures precise welds with minimal errors, but also reduces exposure of human workers to heat and fumes. This is thus a win-win situation! - Polishing and surface finishing

Polishing and surface finishing are labour-intensive processes requiring repetitive actions and fine motor skills. Cobots can execute these tasks with high repeatability and precision. This reduces physical strain on human workers, and provides uniform surface finishes, thus enhancing the product quality. - Machine tending

Machine tending involves monitoring and managing machinery. Cobots can load and unload machines, while also operating them well, ensuring smooth workflow and reduced downtime. This increases machine utilization for repetitive automates tasks, and reduces human error during part handling and machine operation. Cobots are also programmed for 24/7 operation, enabling manufacturers to meet high demand without compromising safety.

For manufacturers looking to implement cobots into their industries effectively, Themis Automation offers expert robotics integration & implementation services, with seamless deployment and customized programming that maximizes productivity, safety, and overall operational efficiency in metal processing environments.

Best practices for implementing cobots in metal processing

To maximize the benefits of cobots, manufacturers should implement some best practices for maximum efficiency.

- All the production processes must be evaluated to identify repetitive, hazardous, or precision-demanding tasks that consume significant time or risk human error. These areas should be prioritized for cobot automation to maximize efficiency.

- Operators should be provided with comprehensive training to effectively work alongside cobots. This will help with productive teamwork, while reducing possibilities of injuries, and also leveraging human expertise for complex operations while robots handle repetitive or high-risk functions.

- Cobots should be carefully programmed and fully integrated with existing machinery, software systems, and production workflows, to enable seamless operation, reduced downtime, and optimized coordination between human and robotic tasks.

- There must be strict safety standards followed and maintained through regular audits, updating protocols, and monitoring cobot operations continuously to ensure a safe working environment.

- The key metrics of productivity, quality, error rates, and machine downtime should be consistently tracked, using the data to evaluate ROI, identify improvement opportunities, and optimize cobot deployment for maximum operational efficiency.

The future of metal processing is undoubtedly robotic, with Artificial Intelligence, machine learning, and advanced sensors coming into demand. Cobots will be responsible for carrying out increasingly complex repetitive tasks. With robotics integration & implementation, manufacturers not only enhance efficiency, but also future-proof their operations, staying competitive in a rapidly evolving industrial landscape. Cobots revolutionize metal processing by combining precision, safety, and productivity, handling tasks from loading and unloading to welding, polishing, and machine tending, while reducing human fatigue and workplace injuries. All in all, the adoption of cobots is a smart business decision that harmonizes human skill with robotic efficiency.