We strive to provide our customers with nothing less than the very best in industrial automation solutions and services that transcend expectations. Our team of skilled experts possess a unique blend of technical finesse and hands-on experience that enables us to offer highly effective, value-based solutions to our customers. As a project-based engineering consulting and product-based trading firm, we are singularly focused on control system design and panel manufacturing. Since our inception in 2009, we have been instrumental in helping hundreds of businesses across diverse industries achieve unprecedented levels of productivity and operational efficiency with our world-class solutions, that transcend borders and boundaries.

View More

We believe that even the best machines can always be improved, and that’s why we offer retrofitting services that assess and modify existing machines for improved functionality and energy efficiency. Our team of experts works closely with our clients to understand their unique needs and deliver customized solutions that drive their business forward.

Read More

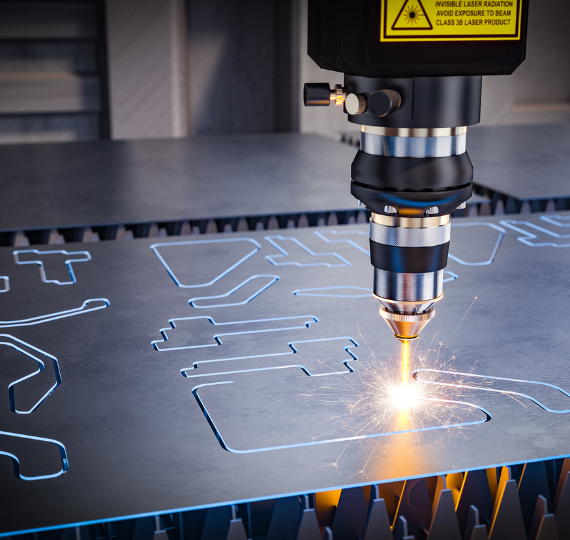

At our state-of-the-art manufacturing facility, we are committed to delivering high-quality control panels that help our customers automate their processes. With a focus on precision and attention to detail, we design and manufacture control panels that are reliable, durable, and efficient.

Read MoreWe have a large portfolio of dedicated and loyal customers across various industries who trust us for our expertise and solutions.

Our customers appreciate our solutions and services. Here’s what some of them have to say:

Ready to build an ecosystem that facilitates productivity, efficiency and safety?

Contact Us